The Real Reason Empire State Building Was Built Using Bricks From A Tiny British Town

The Empire State Building, an iconic symbol of American ambition and architectural brilliance, is known for its towering height, art deco style, and remarkable construction speed. Completed in 1931, it stood as the world’s tallest building for nearly four decades and remains a beloved New York City landmark. But behind its steel skeleton and limestone façade lies a lesser-known detail that continues to astonish history buffs and architecture enthusiasts: the bricks used in its construction came from a small, unassuming town in Britain.

The town in question is Accrington, located in Lancashire, England. This tiny industrial town, far from the towering skyline of Manhattan, played a surprising role in the construction of one of America’s greatest structures. The key lies in a unique material known as Accrington brick — a dense, durable engineering brick famed for its incredible strength and resilience. Locals often call it the “hardest brick in the world,” and for good reason.

Accrington bricks, technically known as Accrington NORI bricks, were originally developed in the 1880s during the height of Britain’s Industrial Revolution. They were produced from local fireclay and fired at extremely high temperatures, resulting in a deep red brick with extraordinary load-bearing capacity. These bricks became highly sought after for building bridges, factories, and, eventually, skyscrapers. Their exceptional quality earned them international recognition — and a place in the foundation of the Empire State Building.

So why import bricks all the way from a tiny British town to build an American skyscraper during the Great Depression? The answer lies in a combination of performance and trust. In the 1920s and '30s, the construction of taller buildings demanded materials that could withstand tremendous pressure. While American-made bricks were widely used, the Accrington NORI bricks had a proven track record of outperforming most others under intense weight and environmental stress.

Engineers and architects responsible for the Empire State Building were unwilling to compromise on structural integrity. When it came to selecting materials for the deepest parts of the foundation and support structure — areas exposed to high pressure and minimal room for failure — the British-made Accrington bricks were chosen. They were used primarily below ground level, forming part of the base that supports the building’s massive steel frame.

Interestingly, the name “NORI” itself is the result of a manufacturing accident. It was originally intended to say “IRON” (to signify the brick’s strength), but a mold was mistakenly cast in reverse. Rather than discard the bricks, the manufacturers kept the name “NORI” — a quirky twist that only adds to the brick’s legend.

The story of Accrington’s bricks and the Empire State Building isn’t just about materials — it’s a reflection of how global trade and industrial craftsmanship crossed oceans to create something magnificent. For a small British town, supplying bricks to the Empire State Building was a source of pride and proof that quality could overcome distance.

Today, the legacy of Accrington bricks lives on, both in the skyscraper that pierces the New York skyline and in the quiet town that produced them. Few tourists standing at the base of the Empire State Building would ever guess that part of its strength comes from across the Atlantic. Yet, in every inch of brickwork deep beneath the city streets, a piece of British history supports an American icon.

News in the same category

RFK Jr. Raises Concerns About 5G Health Risks: Brain Function, EMR, and Cancer Link

People Stunned After Learning The True Meaning Behind ‘SOS’ — It’s Not What You Think

Scientists Reach Bottom Of The Red Sea — What They Found Left Them ‘Shaken’

Taste The Toxin? Shocking Lawsuit Targets Skittles Over Alleged Toxic Ingredient

Antarctica Ice Sheet Grows for First Time in 30 Years, Surprising Scientists

‘Japanese Baba Vanga’ Predicts Mega-Tsunami in July 2025 — Warns of a ‘Boiling Sea’ South of Japan

300,000 Americans On Edge As Massive 11,000ft Volcano Shows Signs Of Imminent Eruption

Wildlife Photographer Captures Alligator With No Bite – Internet Baffled How It’s Still Alive

Scientists Stunned By 3.5 Billion-Year-Old Crater Holding Earth’s Earliest Secrets

Massive 100-Mile-Long Lake Mysteriously Reappears 130 Years After Vanishing

Persistence Hunting: How the San People of the Kalahari Master the Art of Endurance

Halley’s Comet Is Back, But This Time, It’s Raining Fire

Greece Rocked By Massive Earthquake As Tsunami Warning Sparks Panic

Sun Unleashes Monster Flare As Scientists Say Earth Could Be Hit By Massive Solar Storm Tomorrow

Modern House Fires Burn Faster: Why You May Have Only 3 Minutes to Escape

Could the Sahara Desert Power the Entire World with Solar Energy?

Drunk Bees? How Fermented Nectar Affects Honeybees in Australia

How Small Earth Is in the Universe—And Why That Should Inspire Us

News Post

Recognizing Mini-Stroke Symptoms: A Crucial Step in Stroke Prevention

Experts Reveal 3 Warning Signs of Lip and Nail Cancer You Shouldn’t Ignore

Doctor Warns About the Risks of Not Washing Your Hair Regularly

8 Foods That Are Natural Enemies of Tumors – Make Sure to Eat Them Regularly

Medical Experts Warn: 4 Early Morning Signs That Cancer Cells May Be Attacking Your Body

"On the Brink of Cancer: 5 Warning Signs Your Body Sends — Unusual Pain, Persistent Cough? See a Doctor Before It’s Too Late

James Webb Telescope Uncovers Shocking Update on $10 Quintillion Asteroid Psyche

RFK Jr. Raises Concerns About 5G Health Risks: Brain Function, EMR, and Cancer Link

🍊 Detox Naturally: The Surprising Power of Tangerine, Walnuts & Ginger

Boost Your Health with These 2 Powerful Juice Recipes

My SIL Did a DNA Test for My Daughter Behind My Back — When I Learned Her Reason for This, I Went Low Contact with My Brother

People Stunned After Learning The True Meaning Behind ‘SOS’ — It’s Not What You Think

My MIL Demanded I Leave My Own Home During the Birthday Party I Organized for Her – She Didn't Know How Big a Mistake That Was

My Daughter-in-Law Suddenly Started Calling Me 'Mom' After Years of Coldness – I Found Out Why, and I Didn't Let It Slide

My Fiancée Wore a Black Dress to Our Wedding – When I Found Out Her Reason, My Life Was Never the Same

Covid origin FINALLY revealed in bombshell study…and it might not have been China after all

My DIL Forbade Me from Attending My Grandson's First Baseball Game – I Learned the Real Reason and Froze

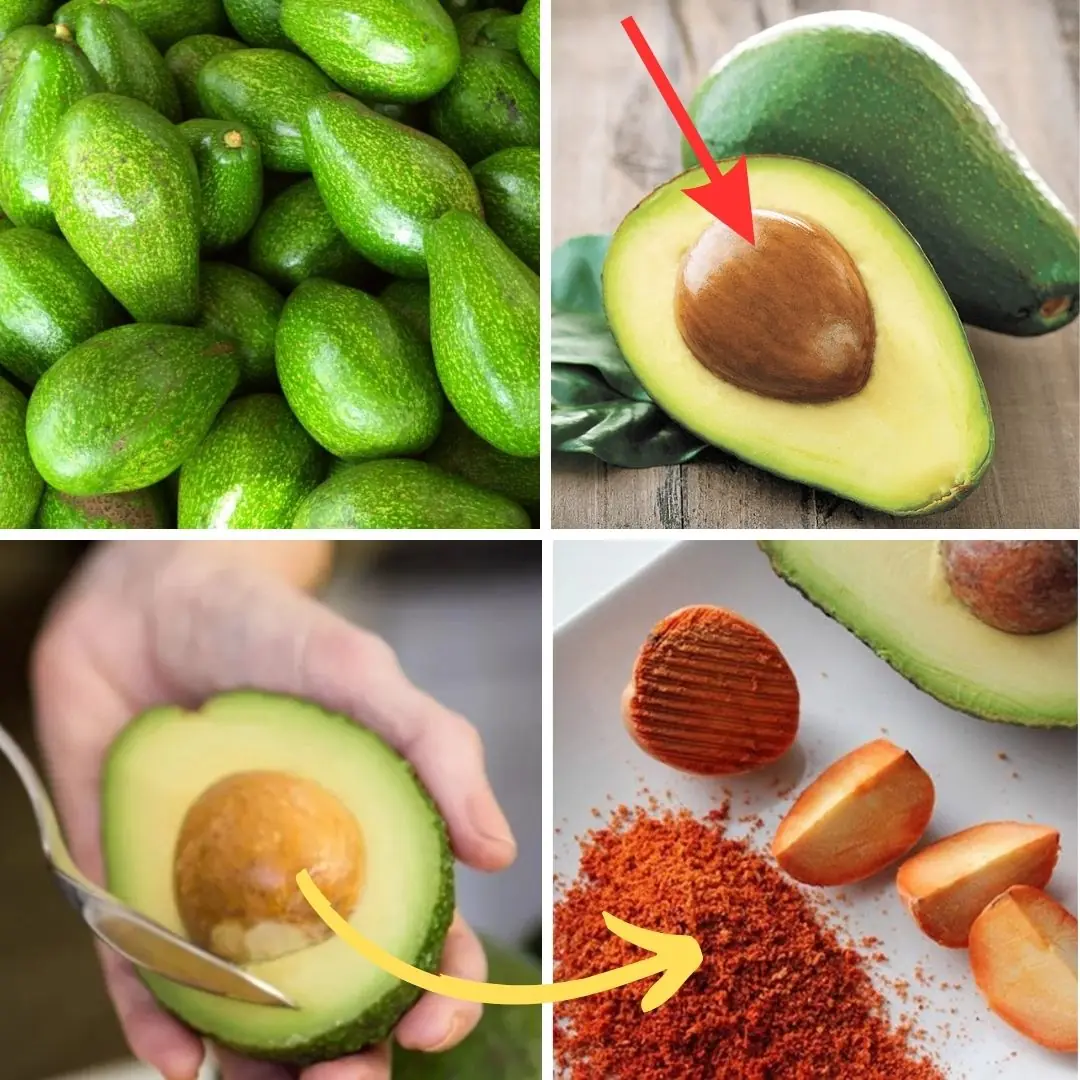

Once You Learn This, You Will Never Throw Avocado Pit Away