Midea Group Unveils MIRO U: A Revolutionary Six-Armed Super Humanoid Robot for Factory Automation

Midea Group, one of China’s largest and most innovative technology conglomerates, has taken a giant leap in the world of factory automation with the launch of its advanced six-armed robot, MIRO U. This cutting-edge "super humanoid" robot is designed to perform highly complex tasks on production lines, marking a significant milestone in the evolution of automation technology. With the ability to enhance production efficiency and optimize repetitive tasks, MIRO U is expected to revolutionize the way manufacturing is done, pushing the boundaries of what robots can achieve in industrial settings.

The MIRO U robot features a humanoid head and torso, giving it a more human-like appearance, but its capabilities extend far beyond mere aesthetics. Equipped with a vertical lifting system, the robot can lift heavy objects and move them with ease. Its design includes a full 360-degree rotation feature, enabling it to perform tasks in every direction without restriction. The robot’s wheeled base provides it with high mobility, allowing it to quickly navigate across production lines, ensuring that it can keep up with the fast-paced demands of modern manufacturing environments.

One of the most exciting aspects of MIRO U is its multi-arm configuration. With six arms, the robot is able to perform tasks that would be difficult, if not impossible, for human workers to execute simultaneously. These arms are designed to work in perfect coordination, combining precision and speed in tasks such as assembly, material handling, and quality control. This multi-arm setup allows MIRO U to handle repetitive manufacturing processes with remarkable efficiency, performing actions much faster and more accurately than a human could.

The robot’s primary purpose is to improve the efficiency of production line changeovers. Midea Group estimates that once MIRO U is fully deployed, it will increase changeover efficiency by around 30%. This improvement could significantly reduce downtime between production shifts, which is a key factor in increasing overall production capacity. The ability to quickly adapt to different tasks without human intervention will not only streamline operations but also reduce the likelihood of errors, further optimizing the production process.

MIRO U’s impact is expected to go beyond just improving the speed of production. By automating repetitive and labor-intensive tasks, it allows human workers to focus on higher-level, more complex activities, thus improving job satisfaction and reducing workplace injuries. Additionally, the robot’s precision and consistency will ensure that the quality of products remains high, making it an invaluable asset in industries where quality control is of utmost importance.

The robot is set to begin pilot testing this month at Midea’s Wuxi High-end Washing Machine Factory, where initial tests are already underway. The company is optimistic that the performance of MIRO U in real-world conditions will meet or exceed expectations, and further deployments will follow if the pilot proves successful. This trial phase will allow Midea to fine-tune the robot’s operations and assess its integration with existing production processes.

If the pilot trials are successful, MIRO U could pave the way for the widespread adoption of humanoid robots in factories worldwide. The robot’s ability to work alongside human employees, performing repetitive tasks efficiently while freeing up workers for more complex roles, marks a significant step forward in the future of manufacturing. As companies continue to seek ways to improve efficiency and reduce costs, robots like MIRO U will likely become an integral part of the global industrial workforce.

The launch of MIRO U also highlights Midea Group’s commitment to innovation and technological advancement. As one of the leaders in the field of industrial automation, the company continues to push the boundaries of what is possible, exploring new ways to integrate robotics and artificial intelligence into manufacturing systems. The successful deployment of MIRO U could set a new standard for factory automation, influencing the development of similar robots in various industries, including automotive, electronics, and consumer goods.

News in the same category

Rapid Pain and Stiffness Relief in Knee Osteoarthritis

Burglar Uncovers Shocking Crime During Robbery, Turns Himself In and Exposes Serious Offense

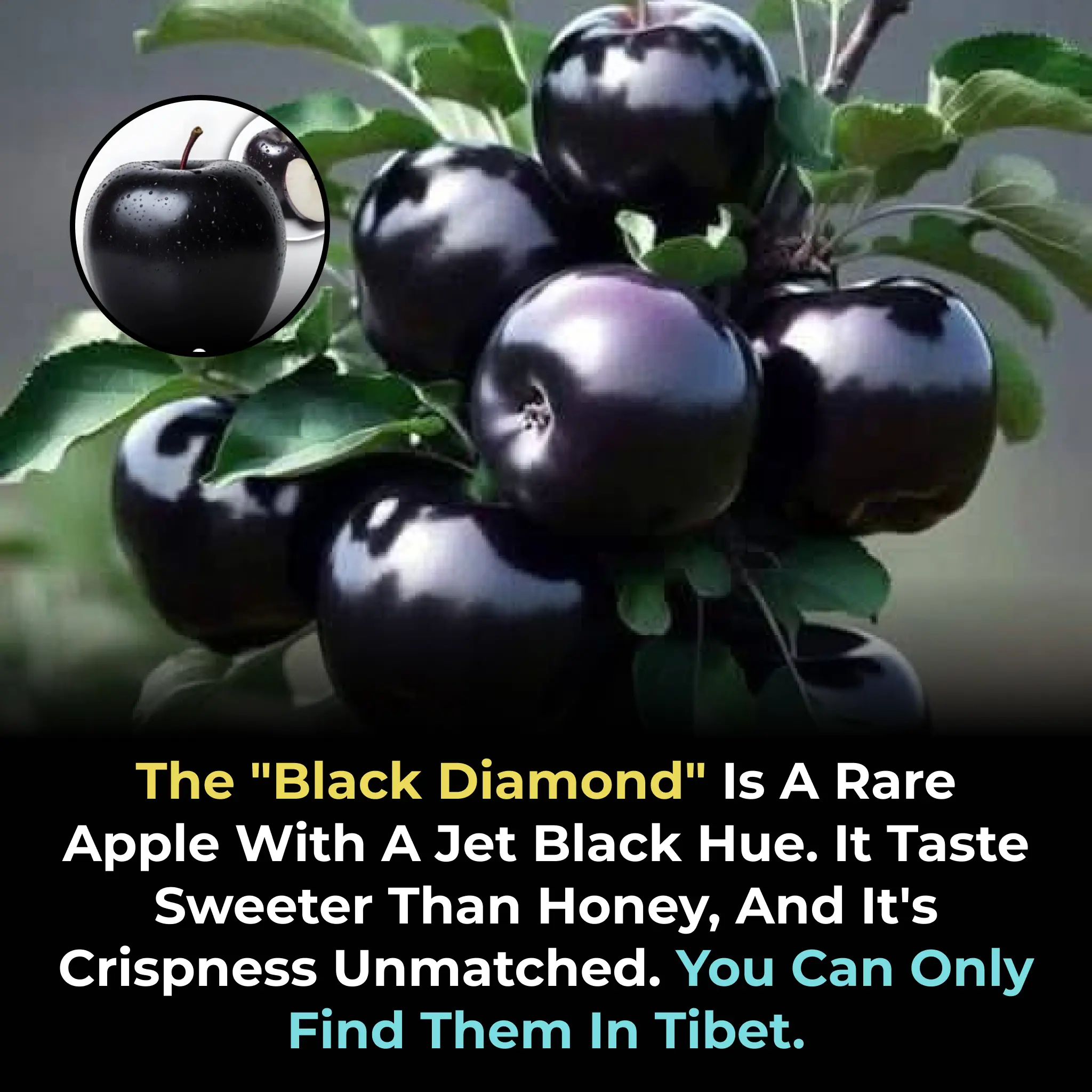

The Black Diamond Apple: A Rare Gem from the Mountains of Tibet

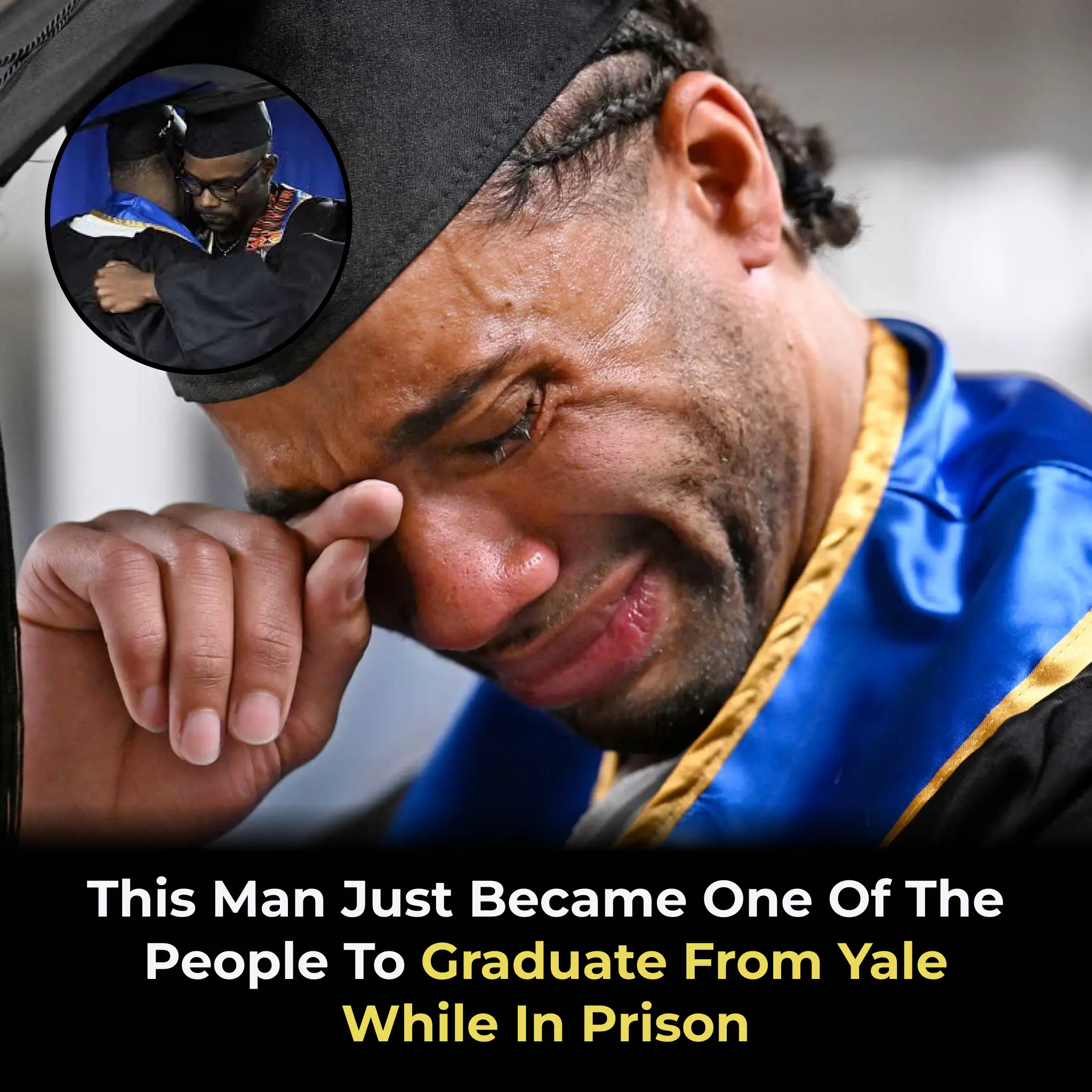

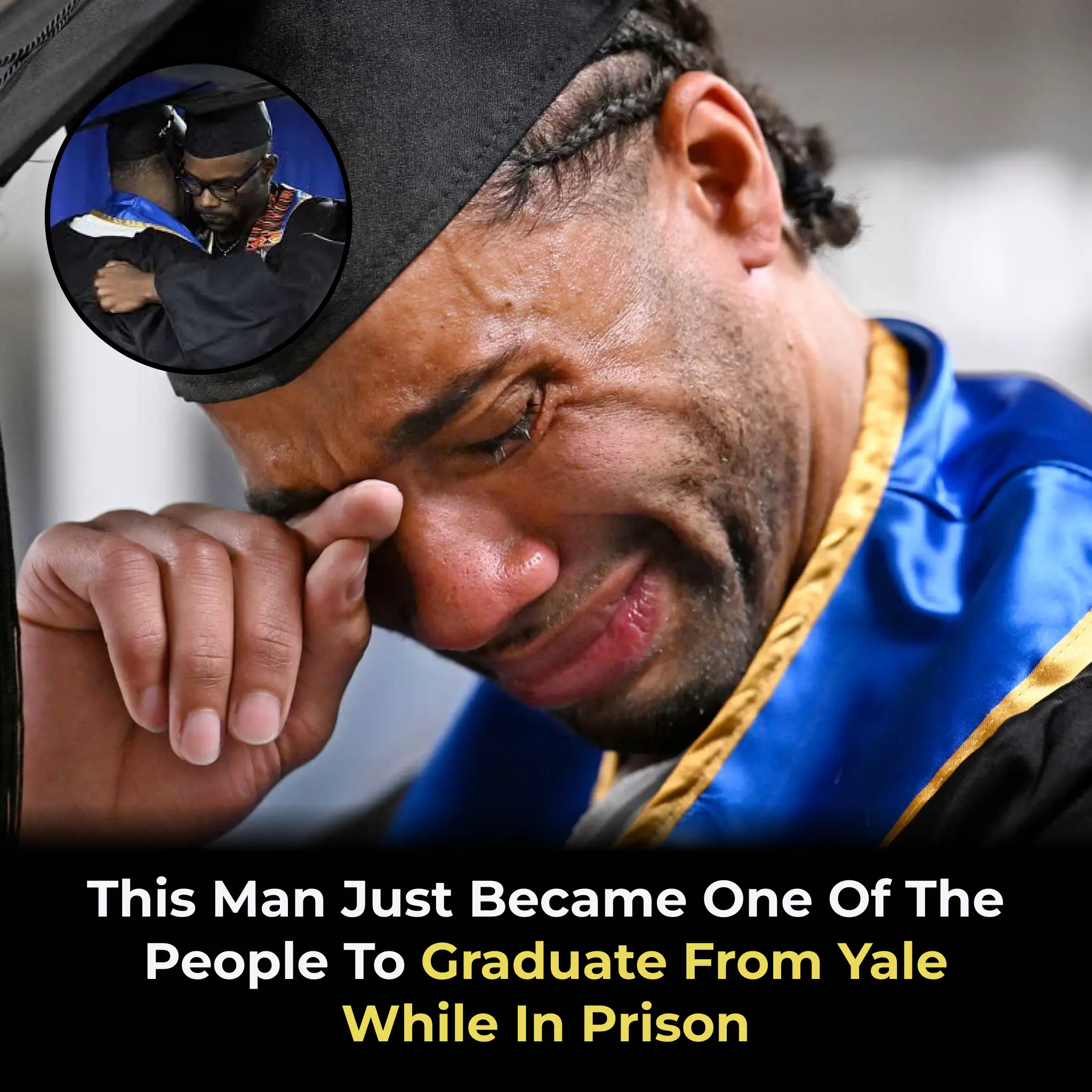

Marvin Harvin Becomes One of the First Incarcerated Individuals to Graduate from Yale University, Highlighting the Power of Education in Prison Reform

Warren Buffett’s Ice Cream Quote: A Simple Yet Powerful Lesson on Taxes

World's Oldest Little Blue Penguin Reaches Remarkable 25 Years in Managed Care

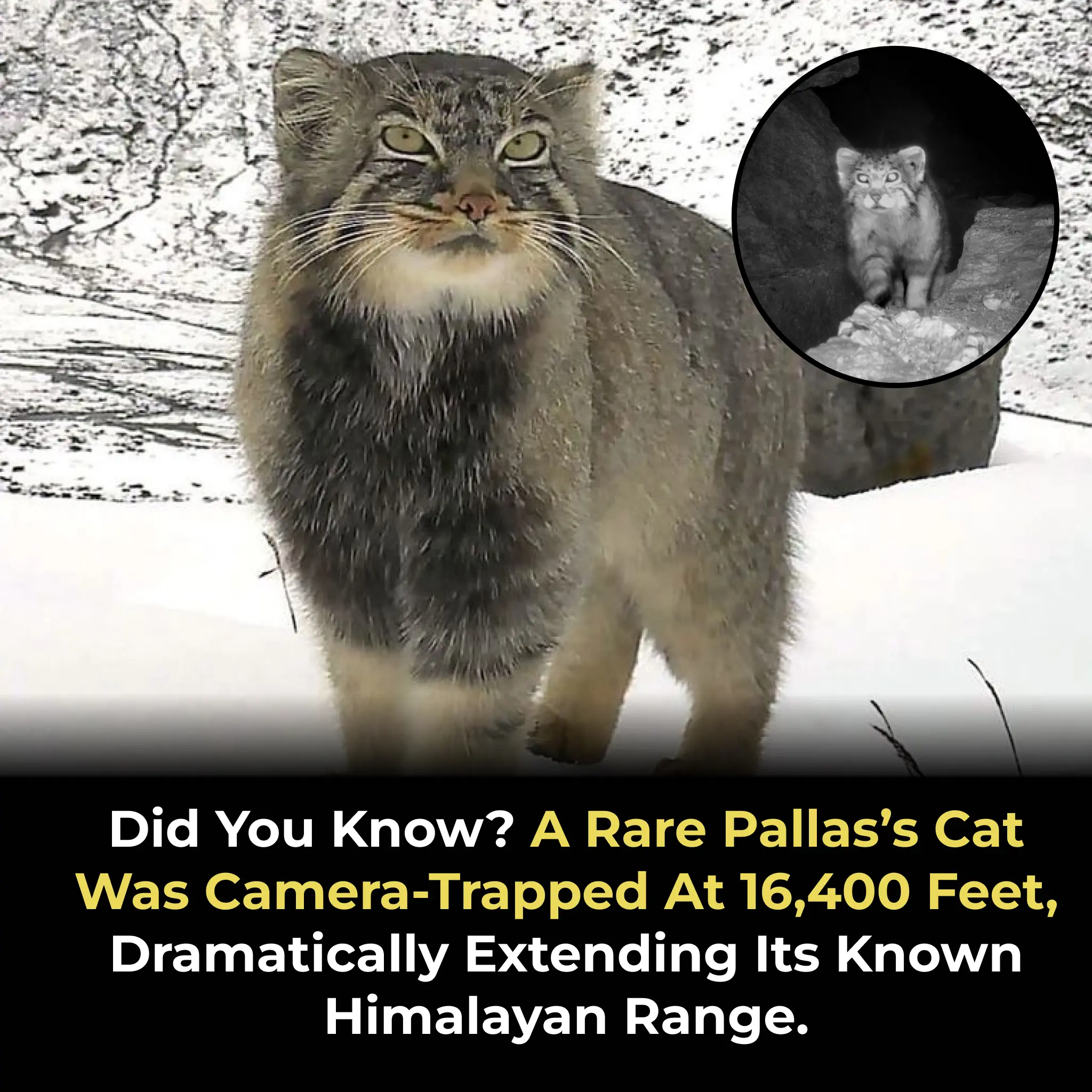

Rare Sighting of Pallas's Cat at 16,400 Feet in the Himalayas Reveals Remarkable Adaptability

Studies Suggest Links Between Swearing, Staying Up Late, and Higher Intelligence

Kenya Records Historic Elephant Baby Boom in National Park: 140 Calves Born in One Year

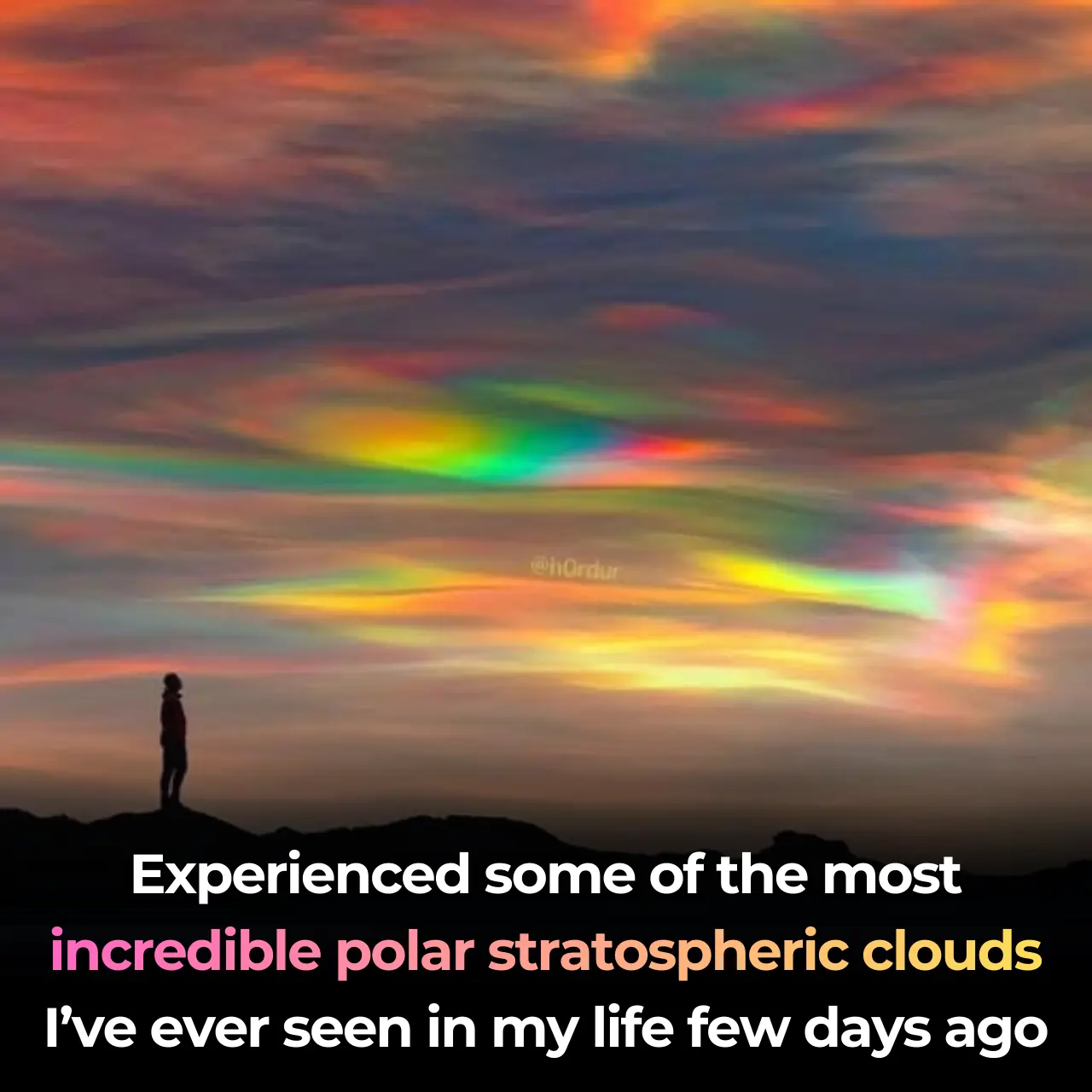

Photograper Captures A Once-In-A-Lifetime Shot Of A ‘Horizontal Rainbow’ That Filled The Whole Sky

Afghan Men Detained for Dressing Like "Peaky Blinders" Characters, Authorities Claim Promotion of Foreign Culture

Austrian Man Arrested for Manslaughter After Leaving Girlfriend to Freeze on Grossglockner Peak

A Touch of Viking Brilliance: Moss-Carpeted Homes in Norway

China Conducts World’s First Wireless Train Convoy Trial, Moving Nearly 40,000 Tons of Cargo

Gene-Edited Immune Cells Reverse Aggressive Blood Cancers in World-First Human Trial

Dutch Artist Berndnaut Smilde Creates Fleeting Indoor Clouds to Explore Transience and Atmosphere

Starlings Obscure the Sky Over Rome: A Dystopian Viral Photo

News Post

A Massive Spider Megacolony Thriving in a Sulfur-Fueled Cave Ecosystem

Rapid Pain and Stiffness Relief in Knee Osteoarthritis

Tamarind: The Tangy Superfruit Your Body Will Thank You For

Why Your Legs Show Signs of Aging First — and 3 Drinks That Can Help Keep Them Strong

Intensive Gum Disease Treatment Slows Artery Thickening, Benefiting Heart and Brain Health

The #1 Food Proven to Support Kidney Cleansing and Protection

High Olive Oil Intake Linked to Significantly Lower Risk of HER2-Negative Breast Cancer

Tight Junction Proteins and Permeability Improved by Roasted Garlic in Mice with Induced Colitis

Randomized Controlled Trial Confirms NEM® Efficacy and Safety in Reducing Osteoarthritis Pain and Stiffness

Whole Fish Trumps Pills: Study Finds Whole-Food Factors, Not Isolated Omega-3s, Lower Autism Risk

Dark chocolate and tea found to significantly lower blood pressure

Burglar Uncovers Shocking Crime During Robbery, Turns Himself In and Exposes Serious Offense

The Black Diamond Apple: A Rare Gem from the Mountains of Tibet

The Power of Pine Needles: 30 Benefits and Homemade Uses

Marvin Harvin Becomes One of the First Incarcerated Individuals to Graduate from Yale University, Highlighting the Power of Education in Prison Reform

The Hidden Power of Pistachio Shells: Benefits and Clever Homemade Uses

Warren Buffett’s Ice Cream Quote: A Simple Yet Powerful Lesson on Taxes

Papaya Seeds: A Powerful Remedy for Liver Health and How to Use Them as a Pepper Substitute

30 Amazing Benefits of Lactuca serriola (Wild Lettuce)